Conveyor rollers are mechanised gadgets used to transport goods around an area with only the minimal time and effort .. These units normally are made up of frames with integral rollers, but sometimes also have wheels or belts. They could either be engine powered or rely upon manual power.

Rollers are usually employed to transfer large materials, and there are various types of rollers for specific roles. Rollers and other conveyors will be able to raise materials, use vibratory motions to safely move materials, and hang from above. Some other key types include screw conveyors, chute conveyors and tow conveyors.

Lets take a closer look at some of the main types of conveyor.

All The Different Conveyor Roller

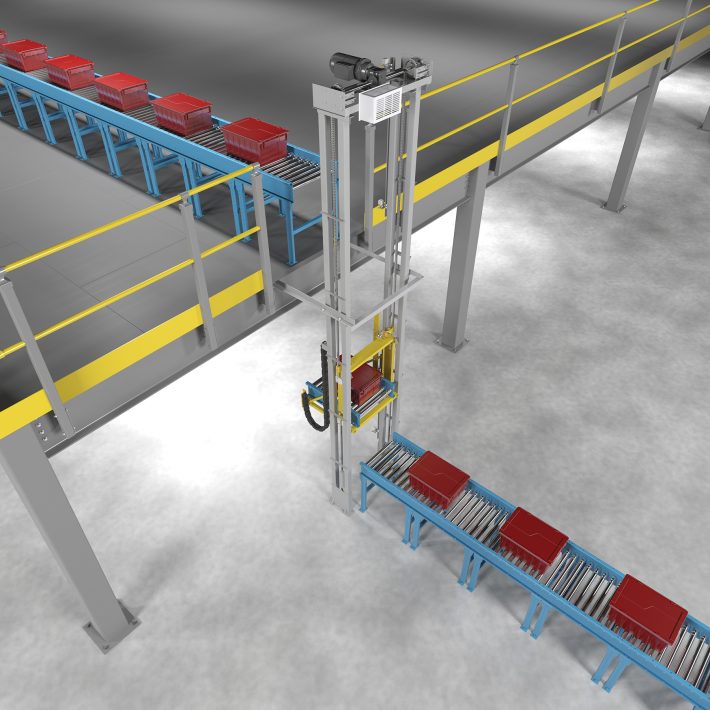

These are handling strategies designed to use rollers mounted in frames to transfer products. The factors it is advisable to take into account would be the load total capacity and height, and also the conveyor length. Roller conveyors are sometimes utilised in handling zones including loading docks, travel luggage handling or assembly lines. Rollers use gravity or manual power to transport goods around and can be straight or curled determined by space or operating environment.

Powered roller conveyors use driven rollers installed in frames to move merchandise and materials around. The key thing to consider is the sort of drive that you need. The principal drive varieties include belts, chains and motors. Powered roller conveyors have numerous functions, which includes food handling, packaging and many other construction line industrial sectors.

Wheel conveyors use unpowered wheels to safely move merchandise, either by gravitational forces or manual power. If deciding on a wheel system, you’ll want to think about load potential, the physical length and width and the electric power needs. Wheel conveyors are normally used for loading and unloading motor vehicles, as well as moving big heavy products such as pallets. Depending on load requirements, wheel numbers and spacing will differ.

www.conveyorrollers.co.uk is regarded as a website that is loaded with lots of up to date info about Roller Supply.

Vibrating conveyors use rotary or linear vibration to move goods or items along. They are commonly used to move bulk materials like gravel and coal. Depending on the required use, many sizes are available.

Overhead conveyors are mounted to ceilings and employ trolleys moved by chains, wires or other connections. They are most typically used in business sectors in which the product must be suspended, for instance parts handling systems, or for a/c needs. Depending upon the planned use of the overhead model, the load transporting capacity could be very critical. A good number of approaches are powered although you can find those which are hand powered.

Belt conveyors use continuous belts to move items. There’re commonly utilised in food services, for baggage handling, in packing and shipping and in the mailing service, even when you would most often relate them with the cash registers in grocery chains. Belt conveyors usually are powered and perform at several rates of speed. Belts might be worked horizontally as well as at inclines.

Beltless magnetic conveyors utilise moving magnets beneath immobile plates to safely move magnetic or ferrous materials. This could be comprising of scrap steel or equipment parts. Beltless magnetic conveyors can be flat, vertical or a mix off both of those.

The Role Of Conveyor Rollers

Your choice of conveyor system depends upon the merchandise model, pace, height and segment focus specific for your business. Various various kinds of conveyor, for example , belts and vibrating units, can be used over long distances in industries such as mining and raw materials. But bear in mind, a vibrating belt system could be of little use in food manufacturing or electronics products business sectors.

Conveyors could very well be hand operated, which is when products are moved along manually over the rollers or wheels. Others are air powered or engine powered. Typically, however, they are driven by electric-powered motors. This either takes place directly or through reduction gears, chains and sprockets.

Materials and things are normally moved on the top surfaces of conveyors, though overhead conveyors could be the obvious exception.

How To Choose A Conveyor Roller

If you’re aiming to transfer commodities quickly coupled with hardly any effort and hard work and the highest level of safety, you ought to take a look at your needs and requirements meticulously. Your eventual choice will be dependent upon the industry in which you work, selecting the power supply (or not) along with the monetary budget that you may have.

Conveyor rollers might be the simplest and highly versatile system and also one of the most affordable. Roller systems are also easy to use and maintain and can be modified to a wide array of businesses and uses. Equipment can be custom-designed to for your available space and rollers can be selected by materials, load capacity, speed capacity and more. This is why conveyor rollers are one of the preferred options for UK organisations.

Roller conveyor solutions can be custom-designed from modular components. These include straight sections, bends, transitions, merges, dividers and a lot more. Manufacturing companies can provide design specialist knowledge and set up support, assisting you to get the very best device for your need. They can also include on-going maintenance support and spares keeping your articles and your business moving.

If it’s time you expanded your business and you plan to reduces costs of processing, storage, shipping and delivery or more, then a conveyor roller system might possibly be precisely what you’ve been searching for.